Cone Flow Article

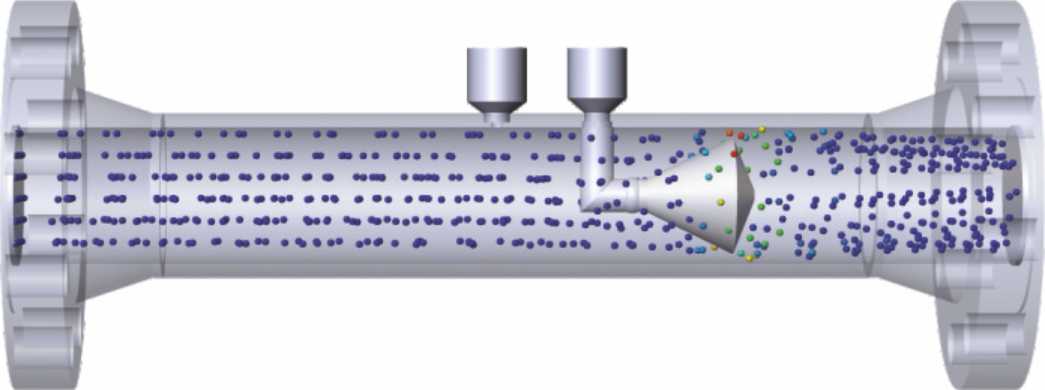

Conical flow elements are a recent development in differen al pressure flow measurement. It works on the same basic principles as other d-p based flow meters but are however designed for high precision measurement that covers a wide range of fluids, flow condi ons and Reynolds-number.

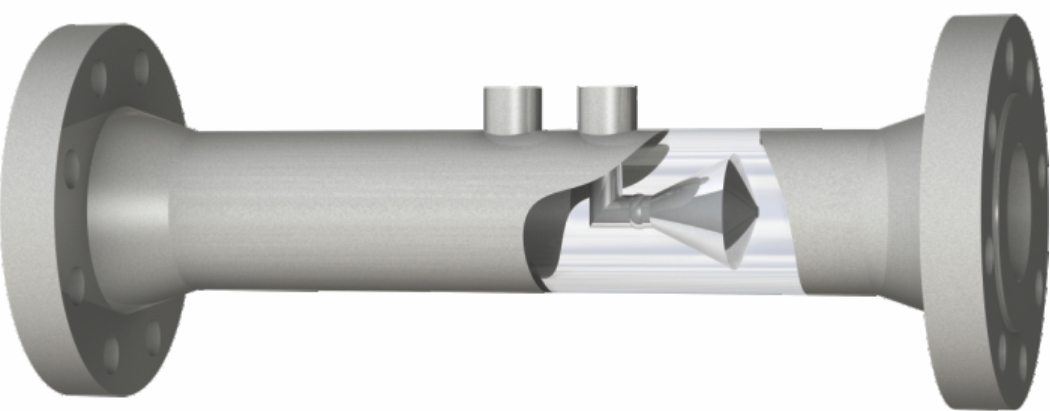

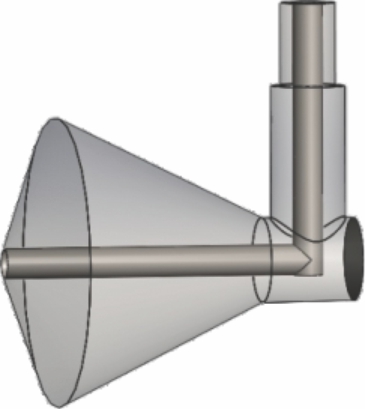

HYDROPNEUMATICS X-FLOW elements produce a differen al pressure as the fluid accelerates along a contoured annular cone, that is installed concentric to the pipe ID. This arrangement helps in op mizing the velocity profile of the flow, thereby providing a more accurate measurement and produces a lower permanent pressure loss. The X-FLOW provides constant co-efficient over a wide range of Reynolds number as compared to other d-p based flow meters.

”MADE” FOR ALL APPLICATIONS

The X-Flow is suitable for all types of process fluids like clean and dirty gases, liquids that are clean, dirty, viscous, corrosive and fibrous or abrasive slurries.

HIGH PERFORMANCE “PACKED” IN ONE INSTRUMENT

The X-Flow is engineered to provide an accuracy of up to ± 0.5% of rate with a repeatability of ± 0.10% or be er, even when used in the most difficult flow and opera ng condi ons. The X-Flow can operate with a broad rangeability (turn down ra o) of 10:1 or higher.

“FIT-IT” OR “RETROFIT-IT”

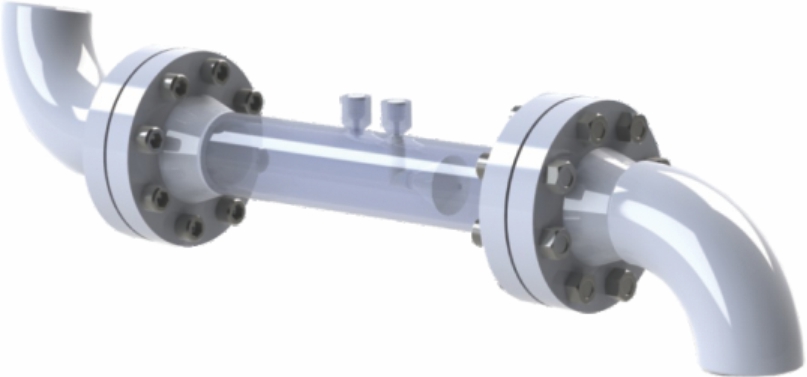

The X-flow can be prac cally installed anywhere in a new piping or even retrofi ed into an exis ng piping in areas where other flow meters may not be able to fit. This means lower installa on costs and lower “down me”.

REDUCED STRAIGHT LENGTHS = REDUCED PROJECT COSTS

Most of the standard d-p based flow elements require very long straight runs on the upstream and downstream sides. This would mean a longer piping layout and high ini al Project costs. The unique X-Flow contour enables it to regulate the turbulent flow profile on its upstream side, thereby, ac ng as a “Flow condi oner” and significantly reducing the straight runs.

MATERIAL/S OF CONSTRUCTION – YOU NAME IT, WE MAKE IT

The X-Flow can be manufactured from a wide range of materials – stainless steels 304 and 316 grades, high Nickel alloys and other exo c grades, carefully selected to suit a wide array of applica ons. The element is machined from forged bar-stock to ensure high mechanical strength required for high pressure services. The machined construc on eliminates weld joints and distor on of the cone profile is minimum.

BUILT TO LAST LONG – REALLY LONG!

Sound engineering prac ces backed by skilled manpower and state-of-the-art machinery ensures a product built to last long. The X-Flow has no moving parts, nor does it require replacement or any maintenance. The contoured shape of the cone also protects itself from flow impacts an abrupt surface keeping its beta ra o intact. The strut type design is also provided with gussets for high flow rates and pressure to minimize vibratory stress. Every X flow is pre-calibrated with 12 points across its full scale at FCRI in Palakkad to determine its co-efficient of discharge which allows for enhanced performance.