Salient Features

ISO Certified

ISO 9001 : 2015, EHS 14001 : 2015, ISO 45001 : 2018 accredited by TUV NORD

Flowel 4.1

Flowel 4.1, Solid Works and Ansys for design of flow elements

Experienced Engineers

Experienced Engineers in Design and CFD

Experts in Manual Calculations

Experts in carrying our manual calculations, when required

All Relevant Standards

All relevant standards Like ISO 5167, BS1042, ISA RP3.2, ANSI B16.36, ASME Codes for pressure vessels & Piping available in the in-house library

Familiar with Leading Consultants

Familiar with specifications of major process control licensors and all leading consultants

Qualified Welders

Qualified Welders as per ASME Section IX, and ASNT certified Quality Control team

IBR Approved

IBR approved Shop

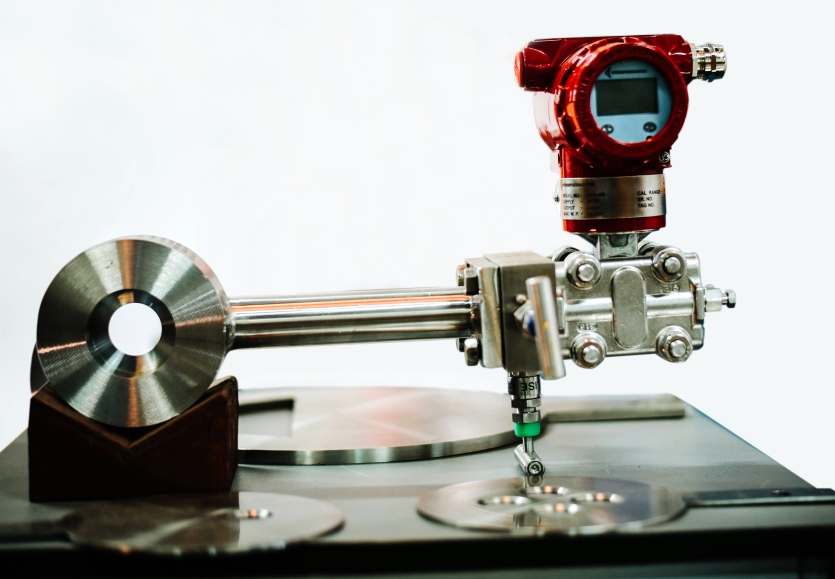

Manufacture and Testing Facility – Machining Equipment

- CNC operated Vertical turning lathe for machining of elements.Orifice plates up to 60” and Flow nozzle elements up to 36”

- Max. turning diameter up to 900mm, turning length up to 600mm in height.

- Profile machining, Internal & external threading, turning and taper turning operations.

- Suitable for standard as well as exotic material grades.

- CNC operated turning center for machining of elements and accessories. Venturies up to 8”

- Max. turning diameter up to 200mm, turning length up to 800mm.

- Internal & external threading, turning and taper turning operations.

- Suitable for standard as well as exotic material grades

- 2 Meter Long Bed Lathes for machining of Machined Venturies up to 10” Line Size, Honing of pipes and machining of Orifice Plated up to 60”

Manufacture and Testing Facility – Fabrication Equipment

- Pulse TIG welding set - up for Fabrication with program control lock.

- Partial & full penetration weld joints, as per Customer spec.

- Weld Procedures established for various material combinations.

- 4 welding stations with certified welders who can carry out GTAW, SMAW and GMAW welding.

- Miller Pro Heat 65 Induction CNC heating and stress releasing machine

- Electronic recording of PWHT cycles.

- 100% operations are OSHAS certified.

- Gadgets such as infrared temperature monitor, Lux meter for DP check, Weldcheck monitor available.

Manufacture and Testing Facility – Testing Equipment

- Oxford X5000 PMI and WAS emission spectrometer

- UTI for tensile testing

- Kraut Krammer Ultrasonic thickness meter

- Hommel surface roughness meter

- LP test with Lux meter and Hydro test up to 1200 bar

- Hardness tester for NACE

- Modosonic Ultrasonic Flaw detector for material integrity

- Fillunger Helium leak test

- Temperature transmitter FF and HART Calibration Communicator

- Third Party Lab Testing Offered –

- - Radiography / X-Ray

- - Magnetic Particle Test

- - Full Metallurgy Profile tests

Manufacture and Testing Facility – Shop Floor

- Plot area of 1290 Sqmt

- Working area of 559.59 Sqmt

- Bifurcated area for machining, fabrication, designed working clean rooms and office.

- Equipped with material handling 5 ton EOT, 2 ton Crane, fork lift, Stacker and trolleys OSHAS & EHS compliant shop floor